What we can offer

Watney can assist with any and all electronics requirements. From the lowest level feedback potentiometer integrated into an actuator, right up to high level processing and software. From circuit diagram to populated PCB and fully commented code.

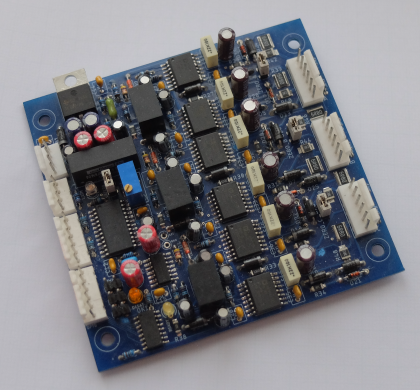

Controller Platform

Complementing our motor-drive specialism is our motor controller platform. This family of motor controllers can be adapted to any brushed or brushless drive. From a single high-side CW/CCW brushed motor drive, through full reversible H-bridge to sensored 3-phase BLDC, this platform is designed to provide bullet-proof reliability during the development process.

Unique hardware-level fast active current limit

Gaining feedback through an on-board hall effect current sensor, this provides the function of a safety clutch, and even when completely stalled, the motor produces less heat than when running at full load.

Commutation angle optimisation

A simple LED provides all the necessary feedback to optimise sensor position for a BLDC application.

Logic-level gate-drive governor

Ties all gate drives to each other in hardware to prevent suicidal drive signals escaping onto the power device(s). Something that’s all too easy in development!

BLDC commutation stage

Designed with through-hole components for ease of adjustment in development (the controller is matched in hardware to the intended motor), this is deliberately over-engineered in terms of component selection. With a primary switch frequency at a low, audible 3kHz and simple block commutation, it is deliberately under-engineered operationally to help get the basics right first time.

Its simplicity is also its strength whereby once a system design has been proven, the controller can be costed-down, transferred to surface-mount and optimised to your specific requirements – for example with inaudible 20kHz+ switching and trap or sinusoidal commutation, software-mappable current limit and full EMC-compliance for production.

BLDC power stage

Constant current capability

All too often (especially in the hobby world), motor controllers are ‘rated’ by the sum of their devices’ peak capacity. Our controllers are rated by their average continuous capability while switching, and yet are still minimised in mass and size. We can always repackage it to your requirements – though we may need to add a heat sink to those requirements!

IGBT-based to provide resilience against voltage spikes during development of battery powered devices, it is literally capable of handling power supplies up to 600V. However it too can easily be optimized for production, for example through changing to cheaper, lower voltage mosfets.

Ultimately the design to your controller can be licensed.

Get in touch

If you have an electronics requirement and are in need of a more robust development controller then get in touch and we can discuss your bespoke requirements.